Are you interested in our solutions? Then write us a message. Our sales team will be happy to help you.

Modern diesel engines no longer make a noteworthy contribution to NOx immission values while retaining their advantage in terms of CO2 emissions and affordability. Not only that: the modern diesel engine is already out on the road.

Michael Krüger

Diesel engines are not always immediately associated with low NOx emissions. This is a mistake, as Michael Krüger explains. After all, modern diesel powertrains barely emit any nitrogen dioxide these days, while particle filters also stifle particulate matter.

In our expert interview, you will learn why long-distance vehicles cannot do without diesel engines, how even carbon neutrality can be made possible in the future, and why modern diesel engines are a key element in the future mix of powertrain technologies.

less CO2 than a comparable gasoline engine.

with the Euro 6 standard, test vehicles equipped with Bosch’s new diesel technology emitted an average of just 13 mg of NOx per kilometer.

for achieving the EU’s fuel-efficiency and emissions targets

Measuring emissions under real operating conditions (real driving emissions or “RDE” for short) makes a major contribution to improving air quality. This also enables the discrepancies between emissions values recorded on a test bench and those resulting from driving profiles on the road to be reduced.

This is because faster acceleration, inclines, stop-and-go traffic, and higher speeds alike are all taken into consideration. Bosch has actively supported the introduction of RDE measurements in recent years.

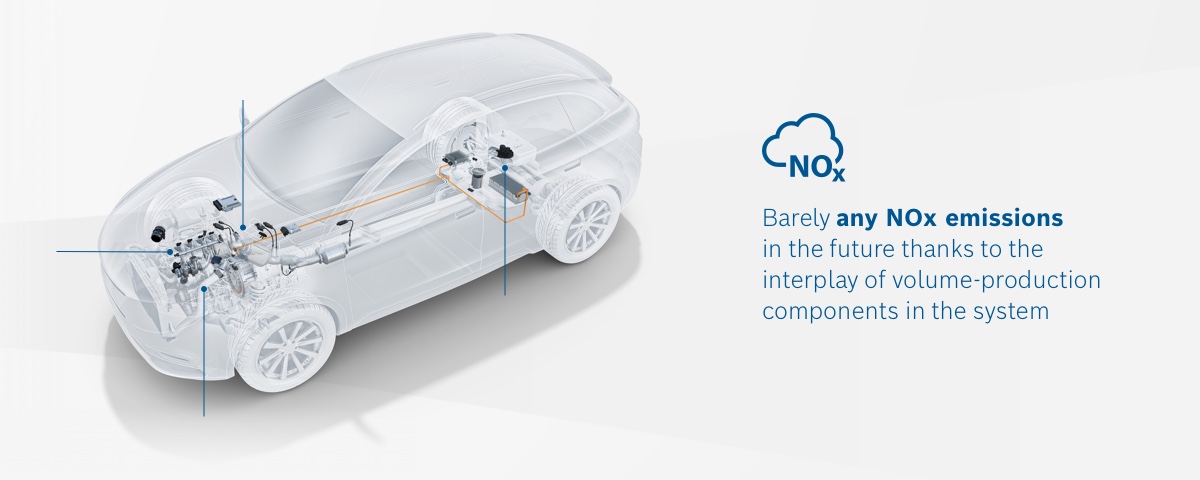

Cold starts are a challenge, which is why developers at Bosch have dedicated so much attention to them. A well-coordinated interplay between engine and exhaust-gas treatment is essential: if the exhaust-gas treatment system is not yet achieving high conversion rates, the engine assists both by increasing the exhaust-gas temperature and with lower raw NOx emissions.

Precise models in the ECU software ensure that measures, particularly those requiring greater amounts of fuel, are only implemented in a targeted manner when they are really necessary.

Diesel-powered cars equipped with Bosch components achieve a NOx value of 13 mg/km thanks to a number of elements: an improved injection system (e.g., with needle-closing control) lowers tolerances. The engine assists exhaust-gas treatment by increasing the exhaust-gas temperature and keeping raw NOx emissions low.

A highly dynamic turbocharger assists in enabling transient driving with exhaust-gas recirculation up to the full load. A double-injection SCR system that doses AdBlue® at two points helps to achieve a further reduction in emissions.

Are you interested in our solutions? Then write us a message. Our sales team will be happy to help you.