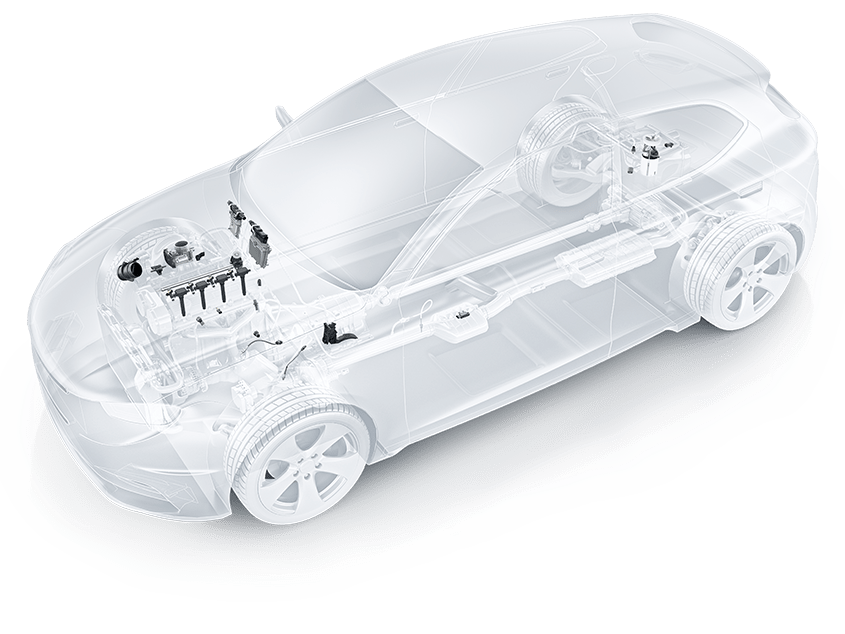

The gasoline port fuel injection is the most popular drive system for gasoline engines worldwide. The powertrain system convinces with low costs, reduced technology and new, innovative further developments.

When using engines with a specific performance of approx. 60 kW/l and downsizing concepts of up to 25%, the gasoline port fuel injection offers significant cost advantages compared with high-pressure direct injection systems. As a low-pressure system (system pressure approx. 6 bar), the gasoline port fuel injection operates with a comparatively simple operating strategy. The complex high-pressure control requirements (system pressure up to 350 bar) are omitted as are the high-pressure pump, the high-pressure sensor, the volume control valve and the high-pressure injectors for multi-point injections. The result is a less complex injection control by means of variances regarding the injection time frame. The robust combustion process of the gasoline port fuel injection also tolerates fuel of lower quality.

60 kW/l

engine performance

efficient

Reduction of CO2- and HC emissions thanks to innovative further development, such as e.g. Advanced PFI or downsizing

25%

Downsizing concepts with turbocharging

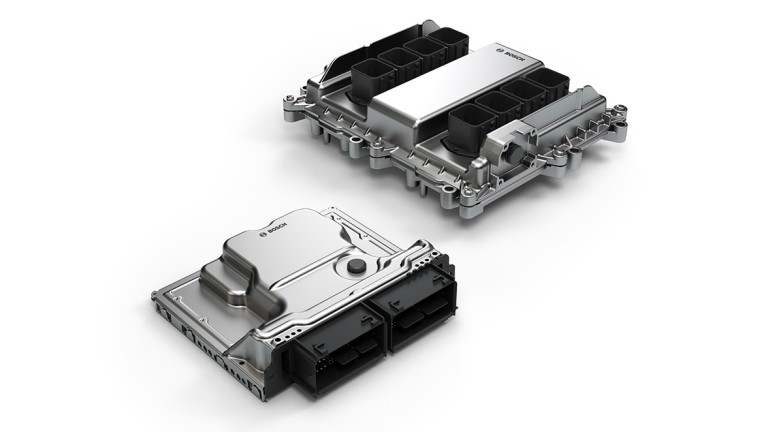

cost-effective

compared with high-pressure systems due to less complex software and injection control